UAE food industry is growing. The growing industry must meet strict food safety laws of the region. How can manufacturers ensure food safety and win trust of their consumers? How can traceability come into play? Get detail in the blog.

Food industry of UAE is growing at a promising rate. It is expected to grow by 5.13 % (CAGR 2023-28) with confectionary and snacks market leading the chart.

Source – https://www.statista.com/outlook/cmo/food/united-arab-emirates

With growing opportunities, come the growing responsibilities. Safe and hygienic food is not only a mandate, but a responsibility of food industry.

To keep regulatory compliance and morality boxes checked, UAE food industry today seems to invest more in modern technology.

In this blog post:

- How to Assure Safety of Food

- Traceability: Why It Is Important

- How Food Traceability Works

- Conclusion

How to Assure Safety of Food:

Quality and safety of food depends upon the quality and safety of raw materials used to produce food. Thus, for any manufacturer, having a check on raw materials is particularly important. To assure that only good quality raw materials are used for production, manufacturer must:

- Buy materials from verified suppliers only,

- Put a quality check on every raw material coming to the warehouse,

- Store the raw material in hygienic and safe condition.

Additionally, manufacturers must quality check the output of the production. This will reassure that there is no contamination in food due to any reason.

A food manufacturing ERP, like BatchMaster can help manufacturers in maintaining list of verified suppliers.

It can also help to put quality checks on raw materials along with that on finished goods. It means, BatchMaster ERP quality checks finished goods before they move to inventory or for delivery.

UAE government is strict towards food safety. Local municipalities of emirates of Dubai and Sharjah ensure that products have correct labels and production & expiry dates for consumption.

ERP for food and beverage industry, like BatchMaster has capabilities to label the food materials in the standard formats and with precise information on it.

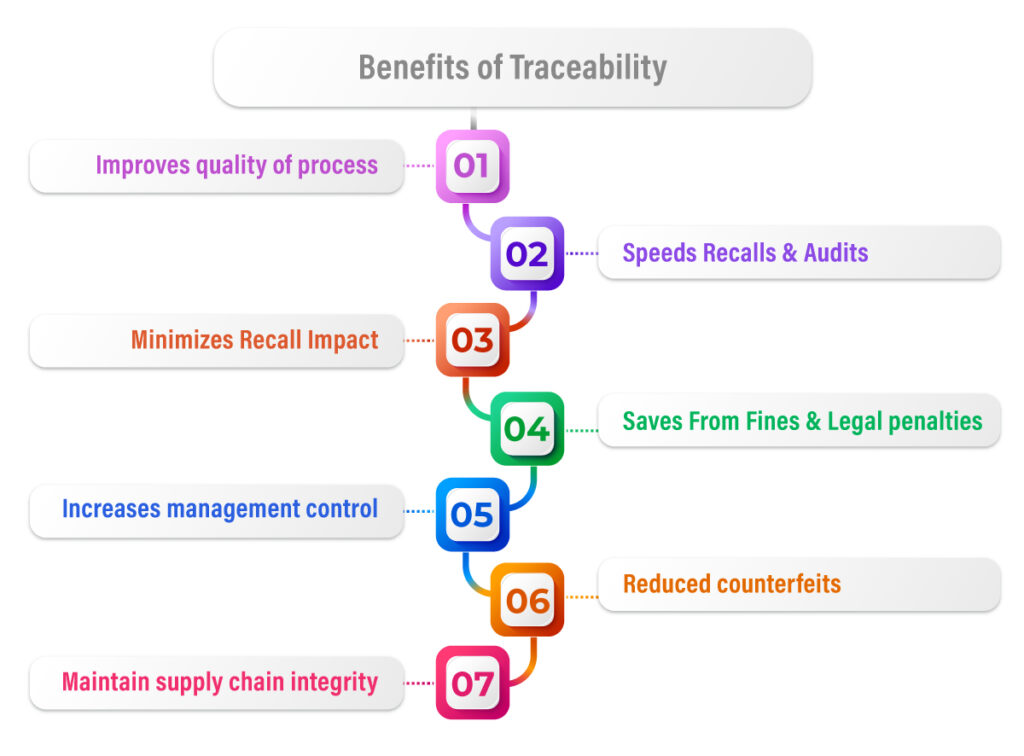

Traceability: Why It Is Important?

In general, traceability is the ability to trace the supply chain. This capability of ERP helps manufacturers to identify the fault area and take necessary action for damage control.

To elaborate, traceability allows manufacturers to see into the supply chain. It allows them to identify raw materials used to make product.

It also keeps track of which batches used selected raw materials. Traceability helps to identify issues related to produced good. If product is sub-standard, manufacturer can track down the supply chain till the raw material and identify the faulty area.

If raw material is sub-standard, manufacturer can track supply chain upstream to find which products used selected raw materials going ahead to which customers they are shipped.

In both ways, manufacturer can control probable damage to its reputation and brand tenacity of their consumers.

Besides, traceability has become a regulatory norm today. Company must have traceability to get compliance in place and save hefty penalties against itself.

How Food Traceability Works?

Abu Dhabi Agriculture and Food Safety Authority ensures food safety in the Emirates of Abu Dhabi and guarantees that the food is safe for human consumption.

Traceability guarantees this safety.

As mentioned earlier, traceability is the ability to trace the supply chain upstream or downstream.

In case of food, which has larger area of impact, traceability becomes especially important. A minor mistake or consumption or substandard quality of food might cause widespread effects.

When manufacturer deploys Food ERP, like BatchMaster, it can track and trace the supply chain.

It means, it can identify which raw materials were used to produce a food item. Conversely, it can also identify which food item/items were produced using selected raw materials.

Since traceability scans the whole supply chain, it scrutinizes each stage of supply chain to identify faults. For example, when a contaminated food product is identified, you could uncover if it happened due to:

- An issue with the supplier

- A faulty machine, or

- Improper handling of items by employees.

Food traceability facilitates product recalls too. Food traceability provides manufacturers amazing product recall ability.

They can recall all the products from the market made by faulty raw materials that too not in days or hours, but in minutes. This drastically impacts the impact of the recall, saving companies from huge fines and brand defamation.

As discussed earlier, traceability helps manufacturers to be compliant with food laws. To be compliant with food laws, a food manufacturer must have a history of:

- Product movement,

- Process through which product went by,

- Product heading towards.

A food ERP can get this history by traceability feature of food ERP like BatchMaster, making the food products compliant to the regulatory laws.

Conclusion:

For food lovers, food is the real essence of life. Food can cross the barriers of countries, continents, and culture. Not only in UAE, but across the globe, consumers seek new taste. This innovation, if backed by safety, and hygiene act as a trust factor for consumers.

Therefore, food industries must do their utmost to ensure safety. They can achieve this by an ERP for food manufacturing like BatchMaster.

Food ERPs have various capabilities to accelerate innovation, drive continuous production, ensure the safety and purity of food, and in case of emergency or regulatory demand, it can facilitate product recalls by providing traceability.

BatchMaster is one such food and beverage ERP which has been serving the industry for more than 30 years. with modules to support various BatchMaster provides bi-directional traceability.

This capability enables manufacturer to collect data points in both – upstream and downstream directions.

So, if you are looking forward to add safety, and hygiene to your food product and wish to be compliant with laws, contact BatchMaster.