BatchMaster Manufacturing for SAP Business One

Harness the power of the best combo ever for recipe/formula-based manufacturers!

Bid-Adieu to hurdles of growth and success. With BatchMaster Manufacturing for SAP Business One, run your business-like a pro! Built-on powerful SAP Business one ERP software, BatchMaster Manufacturing is an all-in-one solution for your distribution, manufacturing, financial, quality and compliance requirements.

Adheres to industry and regulatory compliance

Sit back, relax! When BatchMaster Manufacturing for SAP Business One is in place, compliance with norms and industry is no more a nightmare

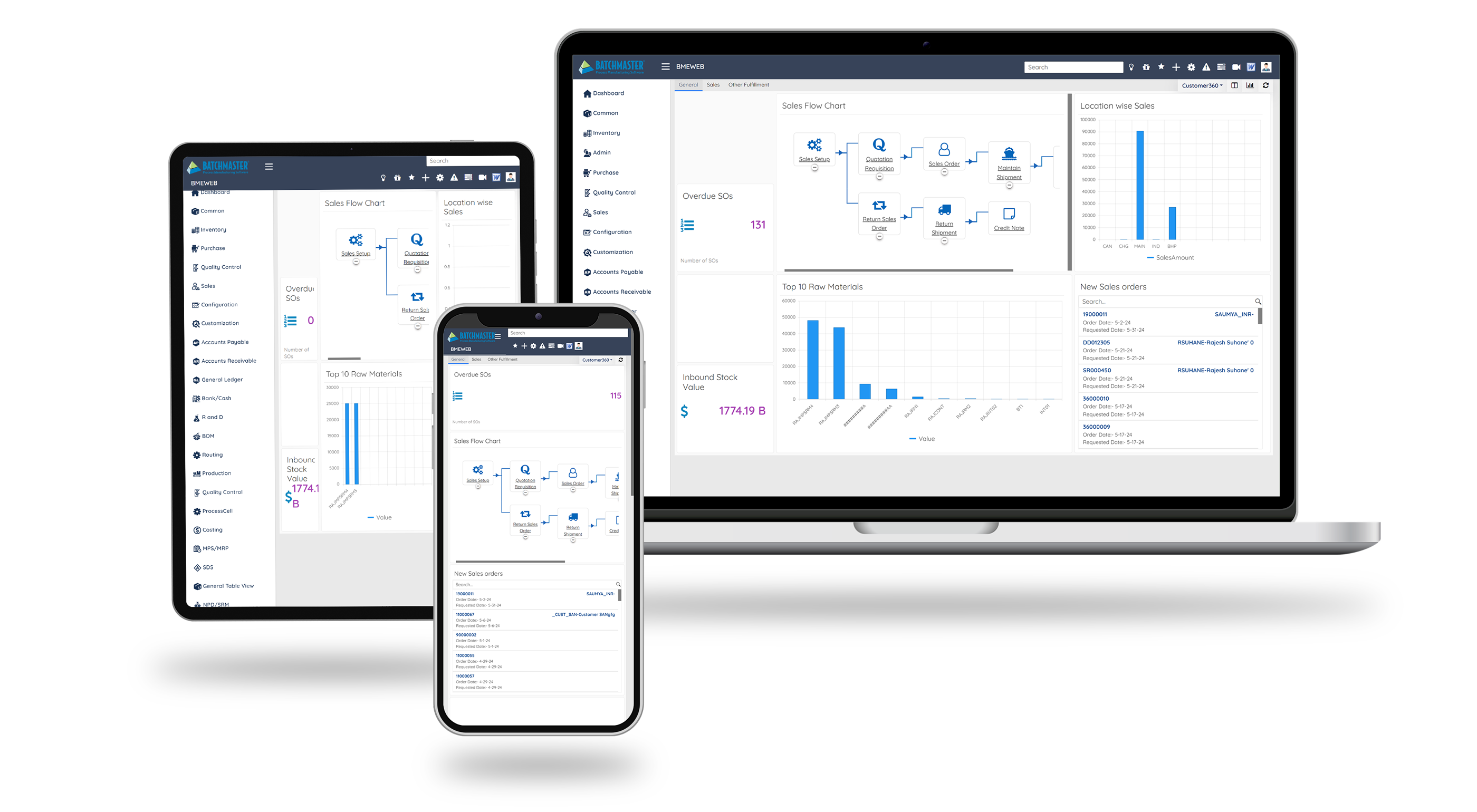

User-Friendly GUI

Similar SAP business One interface and capabilities along with one login and single database to give awesome working experience.

Custom made for your industry

Businesses are unique, their challenges are unique, why not the solutions? Get this precise solution to unique challenges faced by manufacturers in UAE and Middle East

BatchMaster SAP Business One ERP Add Ons:

Having specific business needs? Cater those needs with well-designed add ons of BatchMaster Manufacturing for SAP Business One, such as:

Unleash the ease performing inventory transactions with handheld devices like mobile, tablets, iPads and other such devices.

Control and track your inventory in warehouse down to bin level and get more control over inventory management.

Why BatchMaster Manufacturing for SAP Business One?

- Complete supply chain support

- Built ground-up on solid SAP Business one platform

- Efficient and risk-free processes Compliances are no more complex, as they are adhered to easily

- Real-time information flow

- Quicker and cheaper innovation in product line

- Deeper analysis on trends, demands, sales history, etc. for informed decision making

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally,QuickBooks,Sage 50/100/200/300,SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find the Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs